Screw-Cutting lathe Q1327 pipe threading lathe machines for sale

specifications

Product main technical specifications

| Specifications | UNIT | Q1327 Pipe Lathe | |

| Capacity | Swing over bed | mm | 1000 |

| Swing over cross slide | mm | 610 | |

| Distance between centers | mm | 1500/3000 | |

| Pipe threading range | mm | 130-270 | |

| Width of bed way | mm | 755 | |

| Max.load capacity | T | 5 | |

| Spindle | Spindle bore | mm | 280 |

| Spindle speed steps | - | 12 steps | |

| Spindle speed range | rpm | 16-380 | |

| Chuck size | mm | 800 | |

| Chuck type | - | 4-jaw manual | |

| Turret | Turret type | - | Manual 4 position |

| Tool shank size | mm | 40x40 | |

| Turret travel | mm | 300 | |

| Carriage | X axis feed grade/range | mm/r | 64/0.05-12.15 |

| Z axis feed grade/range | mm/r | 64/0.1-24.3 | |

| X axis rapid traverse speed | mm/min | 1870 | |

| Z axis rapid traverse speed | mm/min | 3740 | |

| X axis travel | mm | 520 | |

| Z axis travel | mm | 1300/2800 | |

| Tailstock | Tailstock quill diameter | mm | 140 |

| Tailstock quill taper | - | MT#6 | |

| Tailstock quill travel | mm | 300 | |

| Motors | Main spindle motor | kW | 22 |

| Rapid traverse motor | kW | 1.5 | |

| Coolant pump motor | kW | 0.125 | |

| Thread | Metric thread grade/range | mm | 30/1-30 |

| Inch thread grade/range | T.P.I. | 27/1-28 | |

| Dimensions | Width x Height | mm | 2100X1600 |

| Length | mm | 6500 | |

| Weight | Net weight | KG | 8000 |

Standard Accessories

1. Tool post

2. Tailstock

3. Chuck

4. Taper guide bar

5. Lighting lamp

6. Coolant pump

7. Rear support bracket

8. Pad iron etc.

Optional Accessories

1. Digital readout

2. Chuck

3. Faceplate

4. Chasing dial

5. Center rest

6. Signal light

7. Protective cover(lead-screw, chuck, tool post)

8. Grinding attachment etc

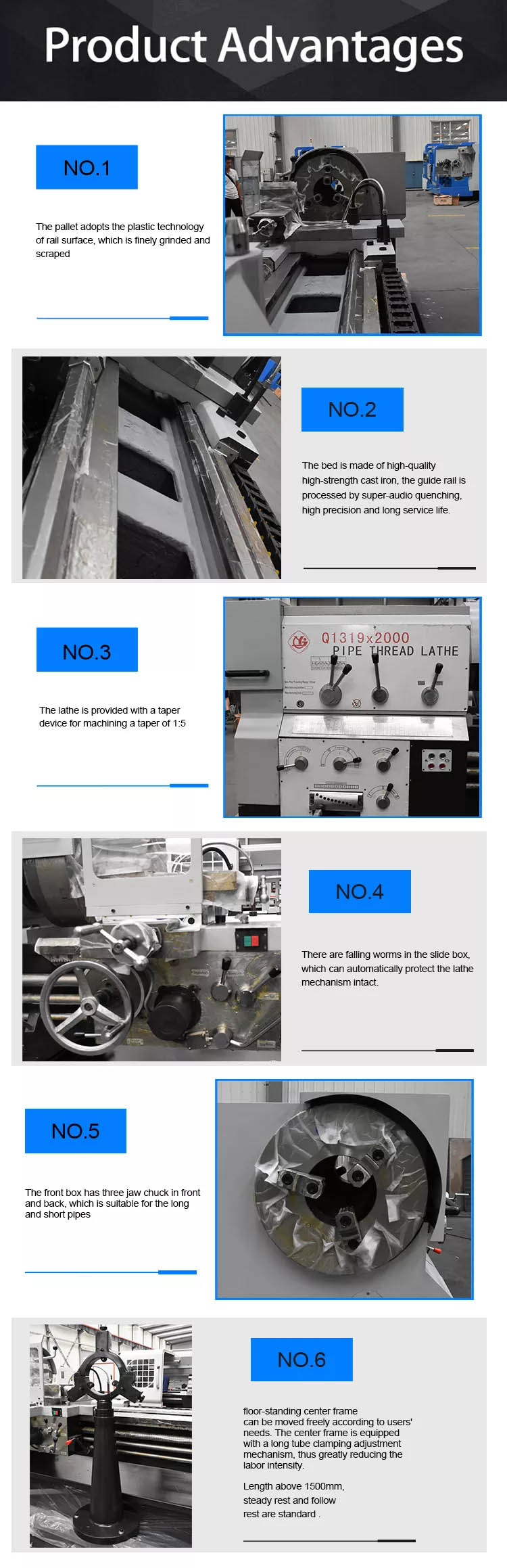

The main performance characteristics

Big spindle bore and double chuck allows clamp and process big diameter pipes. Integral machine bed adopts high strength iron to relize high rigidity and precision. Ultrasonic frequency quenched guide-ways are hard enough for good wear-resistance. Equiped with taper guide bar device this enables the machine to process taper threads.

Write your message here and send it to us