Heavy-duty CNC slant bed lathe machine TCK100 turning and milling compound machine factory direct sales

Product Description

LARGE SPINDLE HOLE PRECISION LATHE:

CNC Lathe use This machine is mainly used for processing various shaft,diskparts,turning can be all kinds of screw thread, arc,cone and plane of internal and external surface, can satisfy the ferrous and non-ferrous metals the speed requirement of high-speed chip. Suitable for cars, motorcycles,electronics, aerospace,military industry and other industries to high efficiency, large quantity and high precision of parts processing. Machining precision can reach level IT6.

technical specifications

|

Technical specifications

|

Unit

|

TCK100

|

|

|

Processing range

|

The maximum turning diameter on the bed

|

mm

|

Φ780

|

|

The maximum turning diameter on the saddle

|

mm

|

Φ500

|

|

|

Recommended Turning Diameter

|

mm

|

Φ650

|

|

|

Center distance

|

mm

|

3100

|

|

|

Chuck clamping processing length

|

mm

|

2900

|

|

|

Spindle |

Spindle head type

|

mm

|

A2-11

|

|

Spindle through hole diameter

|

mm

|

132

|

|

|

Bar stock diameter ≤

|

mm

|

115

|

|

|

Maximum spindle speed

|

r/min

|

1600

|

|

|

Main motor rated output

|

Kw

|

Alpha iI 18 /7000 18.5 / 22kW

|

|

|

The maximum output torque of the main shaft

|

NM

|

708NM

|

|

|

Chuck

|

hydraulic chuck

|

Inch

|

15

|

|

Tailstock

|

Tailstock sleeve

|

mm

|

MT5/6 internal rotation

|

|

Tailstock movement form

|

/

|

Hydraulic/programmable/

fully automatic |

|

|

Saddle

|

slope

|

DEG

|

45 °

|

|

Moving distance X

|

mm

|

350+20

|

|

|

Fast movement speed X/Z

|

m/min

|

16/24

|

|

|

Servo motor X/Y/Z

|

KW

|

3/3/3(4)

|

|

|

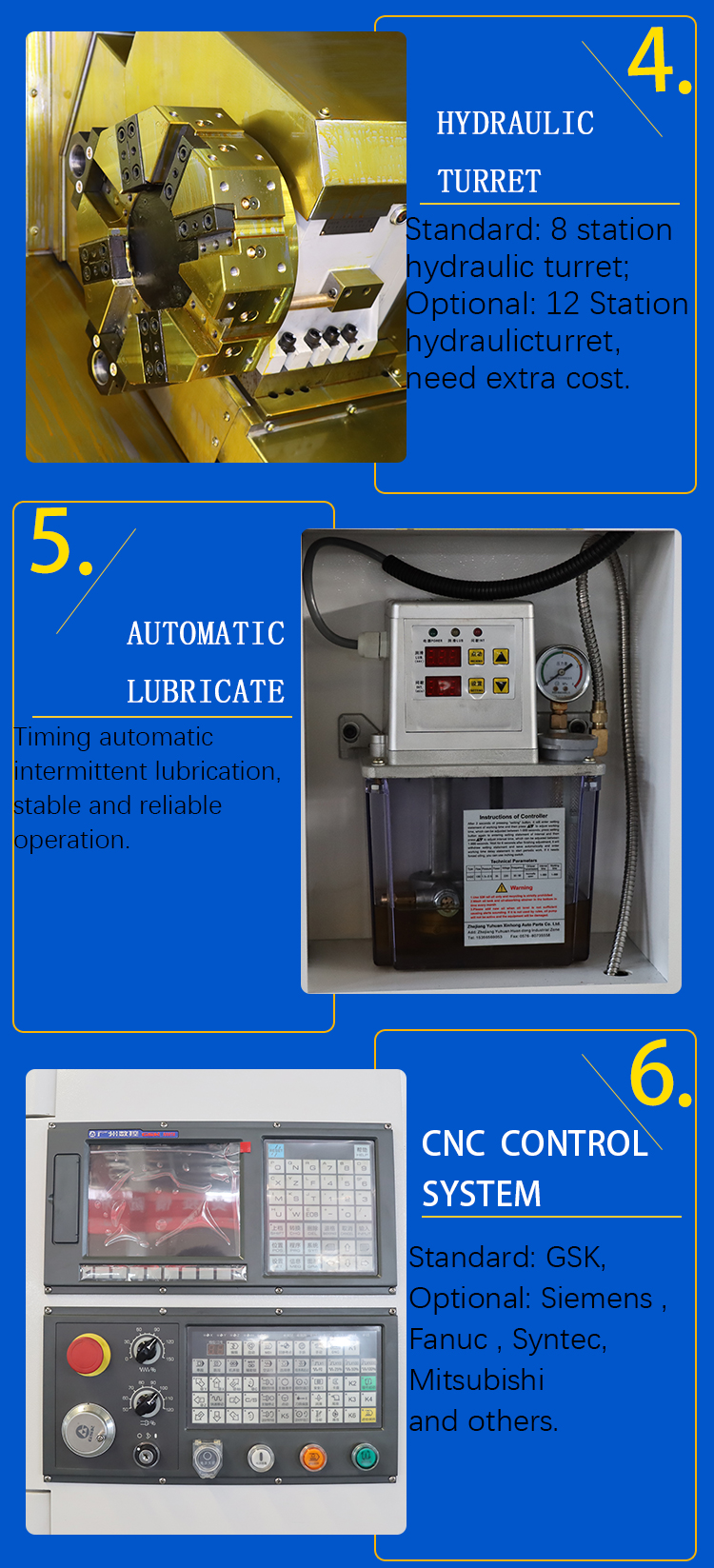

Turret

|

form

|

servo hydraulic/BMT65 Horizontal 12 Stations

|

|

|

Adjacent tool change time

|

S

|

0.5

|

|

|

number of tools

|

/

|

12 Stations

|

|

|

Tool Dimensions (Turning/ Boring)

|

mm

|

32×32/Φ32(40)

|

|

|

Spring collet model

|

/

|

ER40

|

|

|

Power Turret Power

|

KW

|

7.5/11

|

|

|

Y-axis travel

|

mm

|

±75

|

|

|

Dimensions

|

8500X2300X2550mm

|

NW/GW

|

14800/15800KG

|

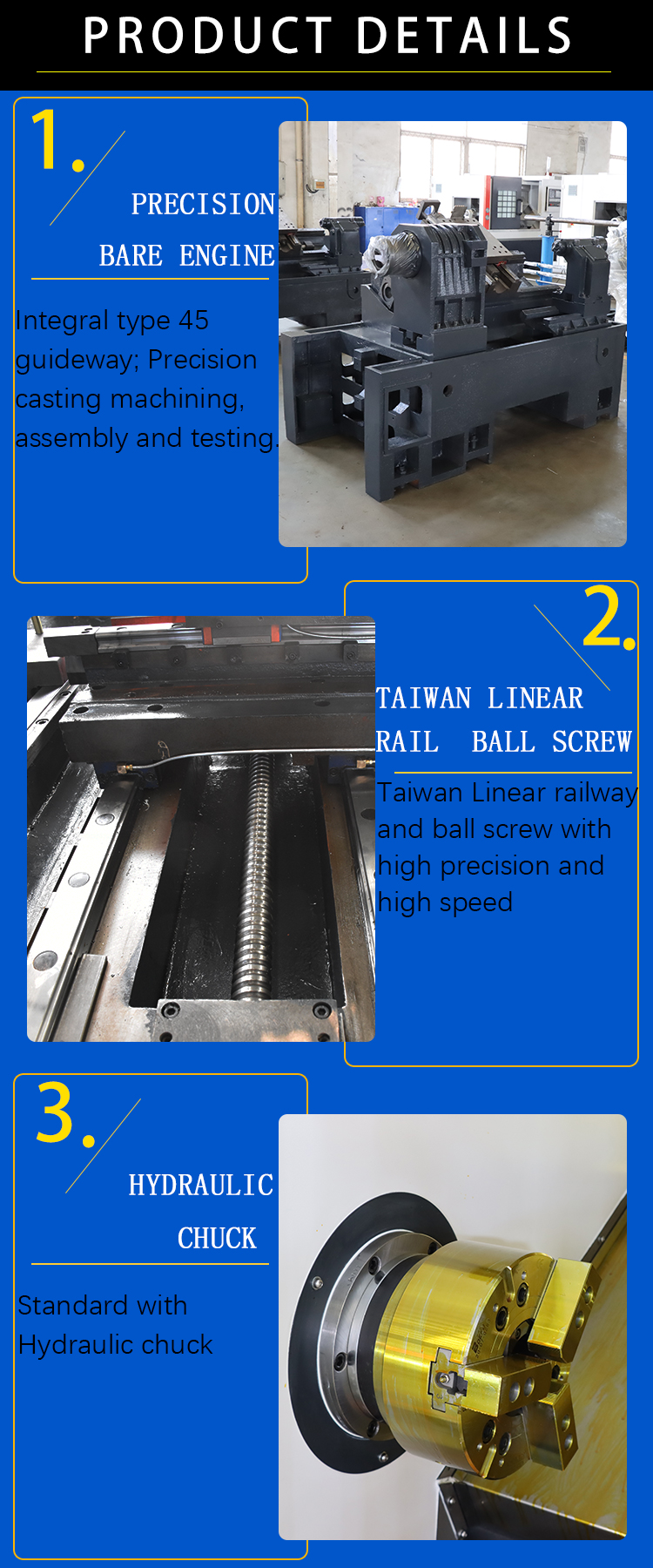

Standard accessories

1. System: GSK

2. Servo spindle motor

3. Stepless speed changer 4- station

4. Gang type tool post

5. Hydraulic chuck

6. Linear rails

7. Lighting system

8. Cooling system

9. Automatic lubrication system

Optional Accessories

- CNC system: KND ,Siemens ,Fanuc etc

- Tool post (turret):-Electric 6-station / 8-station /12-station

- Chuck:Spring chuck ,Hydraulic chuck ,pneumatic chuck

- Feeder:Automatic Bar feeder

- Conveyor:Automatic chip conveyor

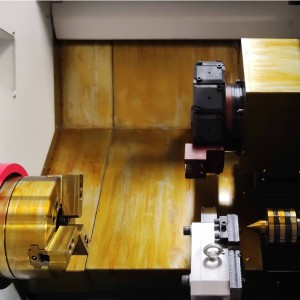

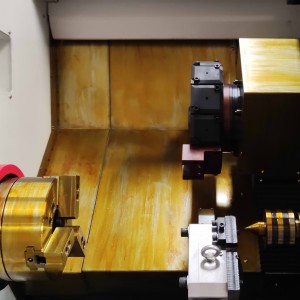

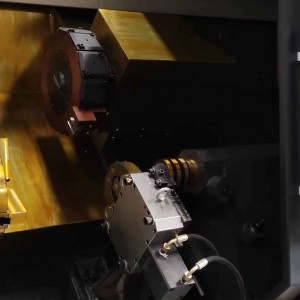

Detailed Images

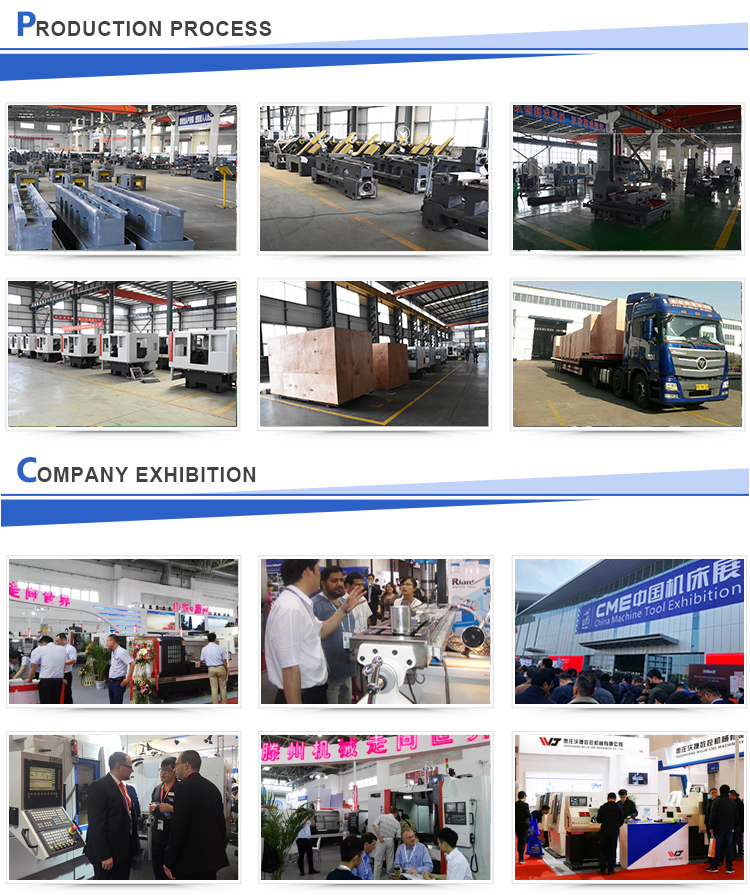

Company Introduction

Packing&Shipping

FAQ

1. What is the payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

When we receive the advance payment, we will start to make production.when the machine is ready , we will take pictures to you.after we got your balance payment. we will send the machine to you.

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine,gear hobbing machine and so on .

3.When is the delivery time?

A: If the machine you will order is standard machine, we can ready the machine within 15 days. if some special machines will be some longer. The ship time is about 30 days to Europe, America. If you are from Australia, or Asia, it will be shorter. You can place order according to delivery time and ship time.we will give you the answer accordingly.

4. What is your trade terms?

A : FOB, CFR,CIF or others terms are all acceptable.

5. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.but we will offer lifetime service for machine.

6. What is the package of the machines?

A: The machines standard will be packed in plywood case.

Contact Us