OEM/ODM Manufacturer Cnc Milling Machine Gantry 3020 - FANUC controller vertical CNC milling machine GMC 1611 heavy cutting double column gantry type CNC machining center – Wojie

OEM/ODM Manufacturer Cnc Milling Machine Gantry 3020 - FANUC controller vertical CNC milling machine GMC 1611 heavy cutting double column gantry type CNC machining center – Wojie Detail:

Product Description

This product X, Y, Z three-axis servo direct control semi-closed vertical machining center, three-axis linear ball guide, guide rail load, span wide, high precision, suitable for heavy load, compact structure and size reasonable, the spindle is servo motor driven by the timing belt. It can realize the clamping of various parts such as discs, boards, housings, cams, and molds at one time. It can be used for drilling, milling, boring, expanding, reaming, rigid tapping, etc. The production of medium and small batch products can satisfy the processing of complex and high-precision parts. The fourth rotary shaft can be equipped to meet the processing requirements of special parts..

CNC milling machine have stronger bearing capacity, three direction guide for quenching hardened rail, guide rail, wide span is big, reasonable, compact structure and dimension spindle for servo motor through the synchronous belt drive.Can be milling and drilling, reaming and reaming and other functions, can be achieved to the plate class, plate class, shells, mold and other complex, high precision parts processing, applicable to many varieties, in a variety of small parts of the plane, inclined plane,groove slots and other process, is the mechanical processing and mould manufacturing ideal processing equipment, canadapt from roughing to finishing processing requirements, has the characteristics of high precision, high efficiency, is widelyused in aerospace, military industry, mould, automobile, internal combustion engines, textile machinery, chemical machinery processing, oil, electronics and other industries.

1.vertical 3 axis mini fresadora cnc for sale : the body casting technology is advanced, the aging process, casting label

2.vertical 3 axis mini fresadora cnc for sale, guide rail are of high precision and high precision.

3. Two type change tool available, manual, pneumatic.

4.metal cvc milling machine with high precision and ATC can be used to step motor or servo motor, to provide customers with a good price.

5. metal cvc milling machine with high precision and ATC Can be customized according to customer requirements of the corresponding products.

The main performance characteristics:

1.mini cnc milling economic machine center is with liner guideways, ensuring the machine’s machining accuracy and stability.

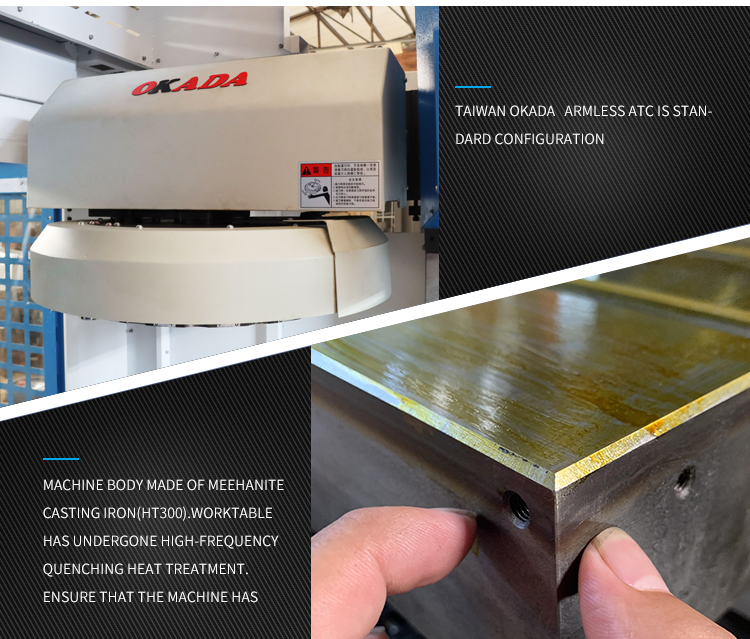

2.The small vmc machine can be with taiwan arm type tool magazine or drum type tool magazine with 10 tools capacity. It can change tools quickly.

3.The machine is with RS232 interface, separated handwheel, spindle blowing chip removal system.

4.The fuselage and main components are high strength cast iron, microstructure stability, ensure the stability of machine tool for long-term use.

5.The column at the bottom of A type bridge type structure, combined with the big box base, greatly reduce the vibration of machine on heavy cutting

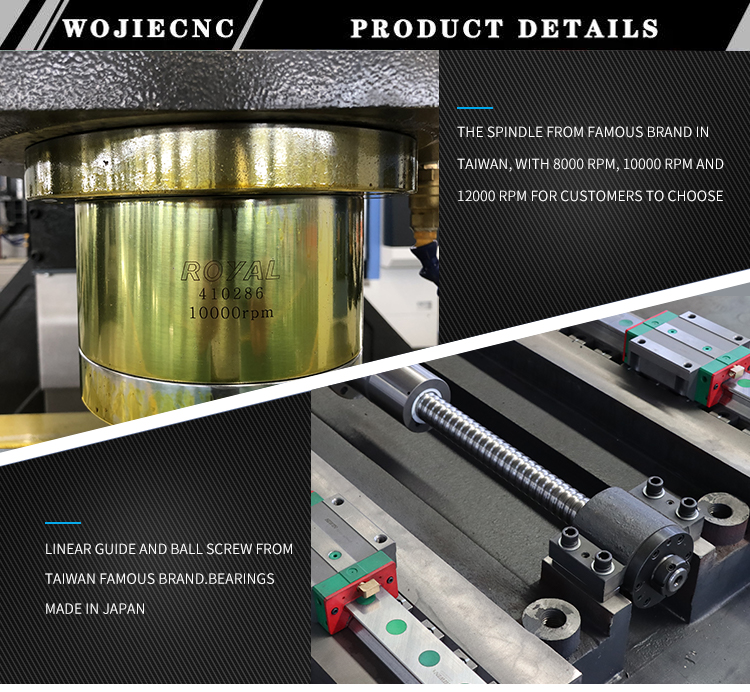

6.The pre tension precision ball screw drive

7.The high speed, high precision, high rigidity spindle unit

8.The design of oil-water separation

9.The intermittent automatic lubrication

10.Automatic scraping knife system

technical specifications

| Table size | 1000X240mm |

| Max. table load | 300kg |

| T slot qty-width*distance | 3-14×75 |

| spindle speed | 8000r p m |

| spindle nose to table surface | 90-470mm |

| Spindle center to Column surface | 360mm |

| Spindle taper | BT40 |

| Main motor power | 2.2/3.7kw (servo) |

| X axis travel | 450mm |

| Y axis travel | 320mm |

| Z axis travel | 450mm |

| X/Y/Z axis rapid feed | 15/15/15m/min |

| Positioning accuracy | ±0.01mm |

| Repeatabeility accuracy | ±0.005mm |

| Net Weight | 2400 kg |

| Overall Dimension | 1900X1620X2000 |

Standard accessories

1.The CNC system: GSK

2.The knife: The famous Taiwan bamboo hat knife.

3.The unclamping cylinder: Taiwan Shangpin

4.The high quality castings: Resin sand casting

5.The spindle: Taiwan famous high speed spindle

6.The screw: HIWIN

7.The bearing: Japan NTN

8.The Internal protection: Total protection

Optional Accessories

1.KND,Siemens FANUC,Mitsubishi 0i mate MD

2.The CNC dividing head

3.The taiwan famous brand manipulator knife storehouse

4.NC rotary table

5.The chip cleaner

6.The fourth axis

Detailed Images

Company Introduction

Packing&Shipping

FAQ

1. What is the payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

When we receive the advance payment, we will start to make production.when the machine is ready , we will take pictures to you.after we got your balance payment. we will send the machine to you.

2: What’s your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine,gear hobbing machine and so on .

3.When is the delivery time?

A: If the machine you will order is standard machine, we can ready the machine within 15 days. if some special machines will be some longer. The ship time is about 30 days to Europe, America. If you are from Australia, or Asia, it will be shorter. You can place order according to delivery time and ship time.we will give you the answer accordingly.

4. What is your trade terms?

A : FOB, CFR,CIF or others terms are all acceptable.

5. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.but we will offer lifetime service for machine.

6. What is the package of the machines?

A: The machines standard will be packed in plywood case.

Contact Us

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for OEM/ODM Manufacturer Cnc Milling Machine Gantry 3020 - FANUC controller vertical CNC milling machine GMC 1611 heavy cutting double column gantry type CNC machining center – Wojie , The product will supply to all over the world, such as: Mauritius, Hongkong, Atlanta, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.