QC12Y Pendulum Shearing Machine Price Offer

Product Description

10 Feet Shearing Machine Steel Plate Cutting Machine QC12Y 8X3200 Sheet Metal hydraulic cutting shear machine Packaging :plywood case

technical specifications

|

Model

|

Plate thickness

|

Plate width

|

Material strength

|

Shear angle

|

Back gauge stroke

|

Travel times

|

Between column

|

Main motor power

|

Outline dimension

|

|

QC12Y

|

mm

|

mm

|

KN/cm

|

°

|

mm

|

Mm-1

|

mm

|

kw

|

mm

|

|

4X2500

|

4

|

2500

|

450

|

1°30’

|

20-500

|

18

|

2700

|

5.5

|

3120X1450X1550

|

|

4X3200

|

4

|

3200

|

450

|

1°30’

|

20-550

|

12

|

3410

|

5.5

|

3520X1560X1670

|

|

4X4000

|

4

|

4000

|

450

|

1°30’

|

20-550

|

12

|

3410

|

5.5

|

4340X1620X1660

|

|

4X6000

|

4

|

6000

|

450

|

1°30’

|

20-800

|

8

|

6270

|

7.5

|

6460X2100X3100

|

|

6X2500

|

6

|

2500

|

450

|

1°30’

|

20-550

|

18

|

2720

|

7.5

|

3000X1600X1610

|

|

6X3200

|

6

|

3200

|

450

|

1°30’

|

20-550

|

15

|

3420

|

7.5

|

3840X1700X1680

|

|

6X4000

|

6

|

4000

|

450

|

1°30’

|

20-550

|

15

|

4220

|

7.5

|

4300X1610X1680

|

|

6X6000

|

6

|

6000

|

450

|

1°30’

|

20-800

|

8

|

6280

|

11

|

6500X2200X2200

|

|

8X2500

|

8

|

2500

|

450

|

1°30’

|

20-550

|

18

|

2720

|

7.5

|

3120X1700X1650

|

|

8X3200

|

8

|

3200

|

450

|

1°30’

|

20-550

|

12

|

3420

|

7.5

|

3840X1700X1680

|

|

8X4000

|

8

|

4000

|

450

|

1°30’

|

20-500

|

8

|

4240

|

11

|

4750X1750X1850

|

|

8X6000

|

8

|

6000

|

450

|

1°30’

|

20-800

|

6

|

6350

|

15

|

6530X2200X2020

|

|

10X2500

|

10

|

2500

|

450

|

1°30’

|

20-500

|

10

|

2720

|

15

|

3150X1850X1900

|

|

10X3200

|

10

|

3200

|

450

|

1°30’

|

20-500

|

8

|

3420

|

15

|

3900X1800X1700

|

|

10X4000

|

10

|

4000

|

450

|

1°30’

|

20-500

|

8

|

4260

|

15

|

4730X2200X2100

|

|

10X7000

|

10

|

7000

|

450

|

1°30’

|

20-800

|

5

|

7365

|

18.5

|

7750X2620X2320

|

|

12X2500

|

12

|

2500

|

450

|

2°

|

20-800

|

10

|

2860

|

15

|

3380X1900X1900

|

|

12X3200

|

12

|

3200

|

450

|

2°

|

20-800

|

10

|

3480

|

15

|

3900X2100X1960

|

|

12X4000

|

12

|

4000

|

450

|

1°40’

|

20-800

|

8

|

4290

|

15

|

4720X2100X2020

|

|

12X6000

|

12

|

6000

|

450

|

1°40’

|

20-1000

|

8

|

6250

|

18.5

|

6850X2500X2320

|

Standard accessories

10 Feet Shearing Machine Steel Plate Cutting Machine QC12Y 8X3200 Sheet Metal hydraulic cutting shear machine Packaging :plywood case

Optional Accessories

1.The appearance of beautiful and generous overall layout coordination

2.Fuselage, vertical column, sliding seat are all rectangular guide, good stability

3.Guide rail to take automatic quenching, high wear resistance

4.Digital synchronous display, intuitive and accurate, can improve the efficiency of low cost

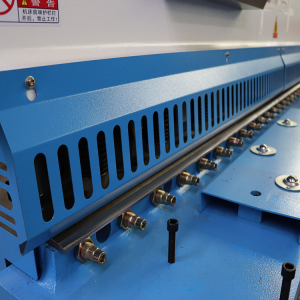

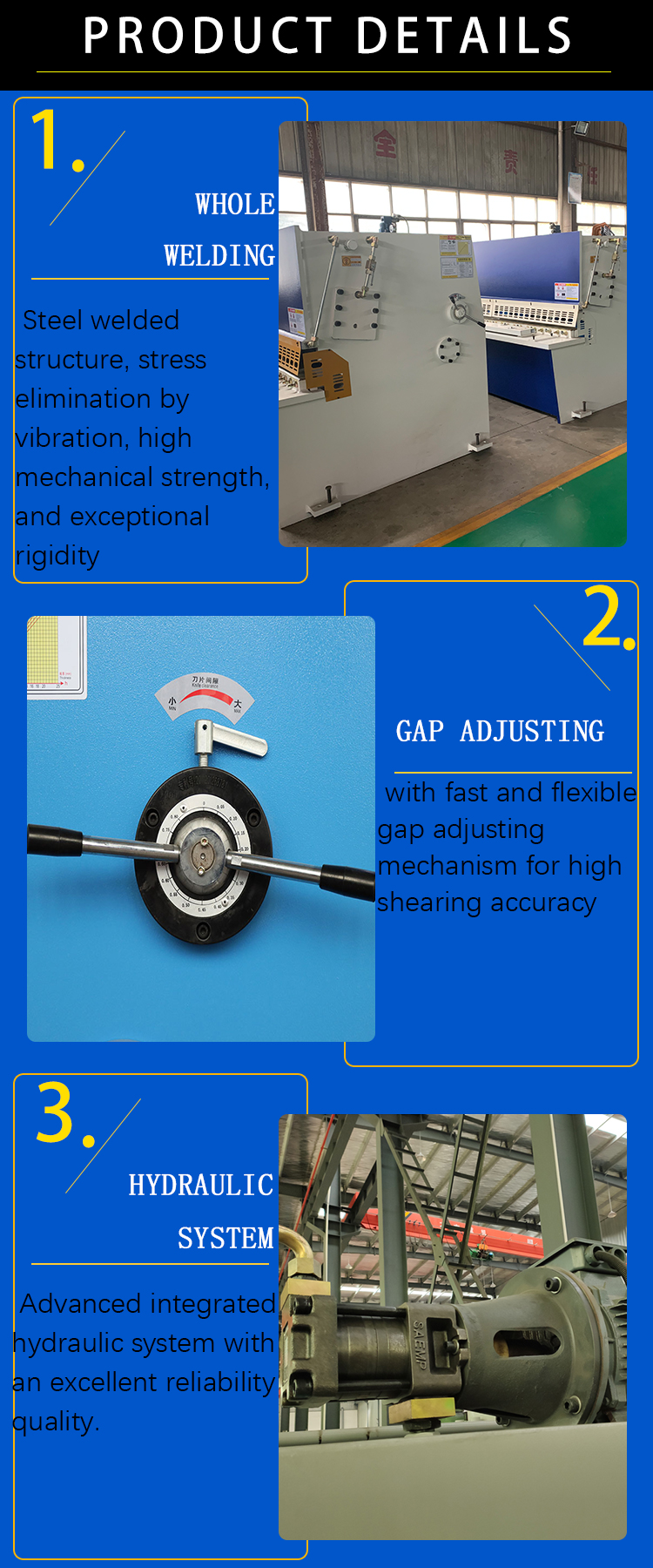

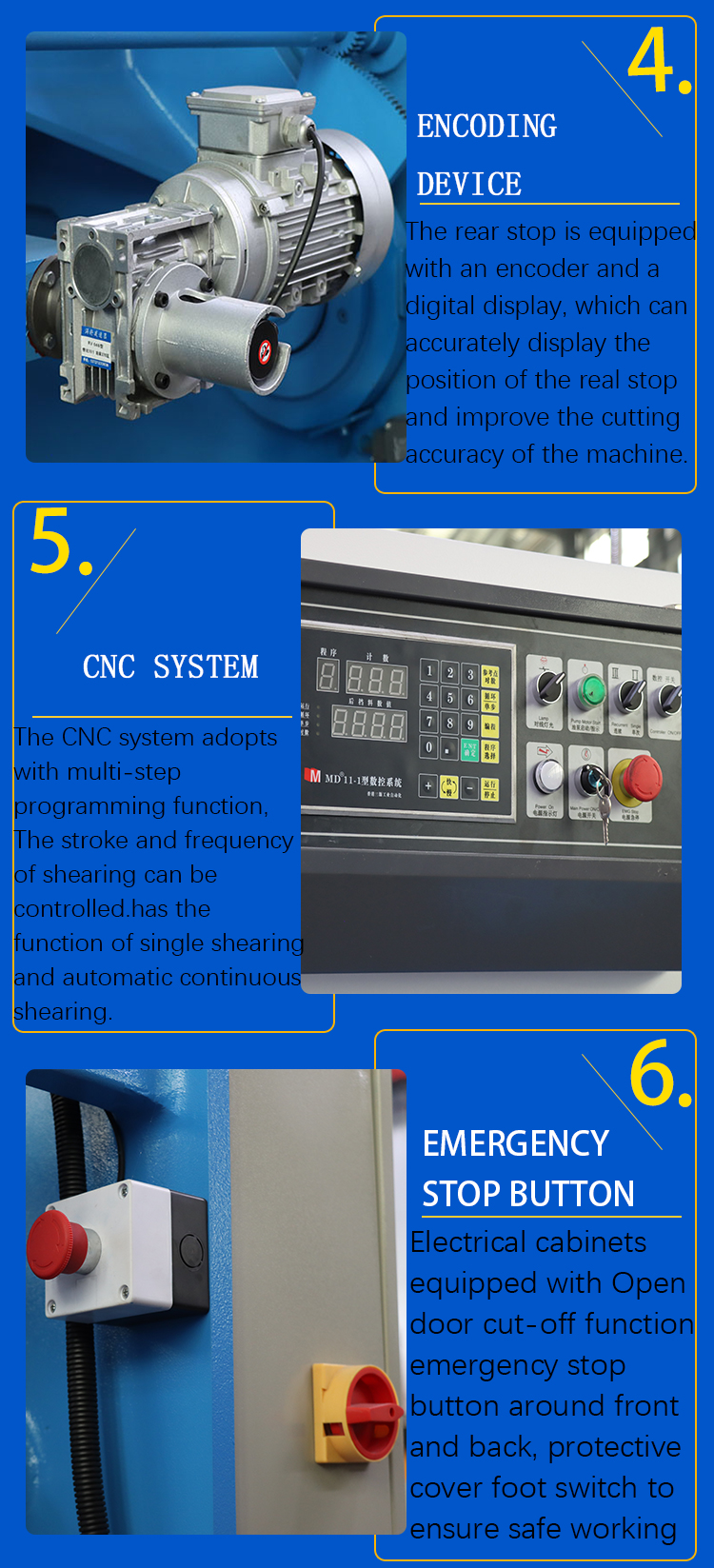

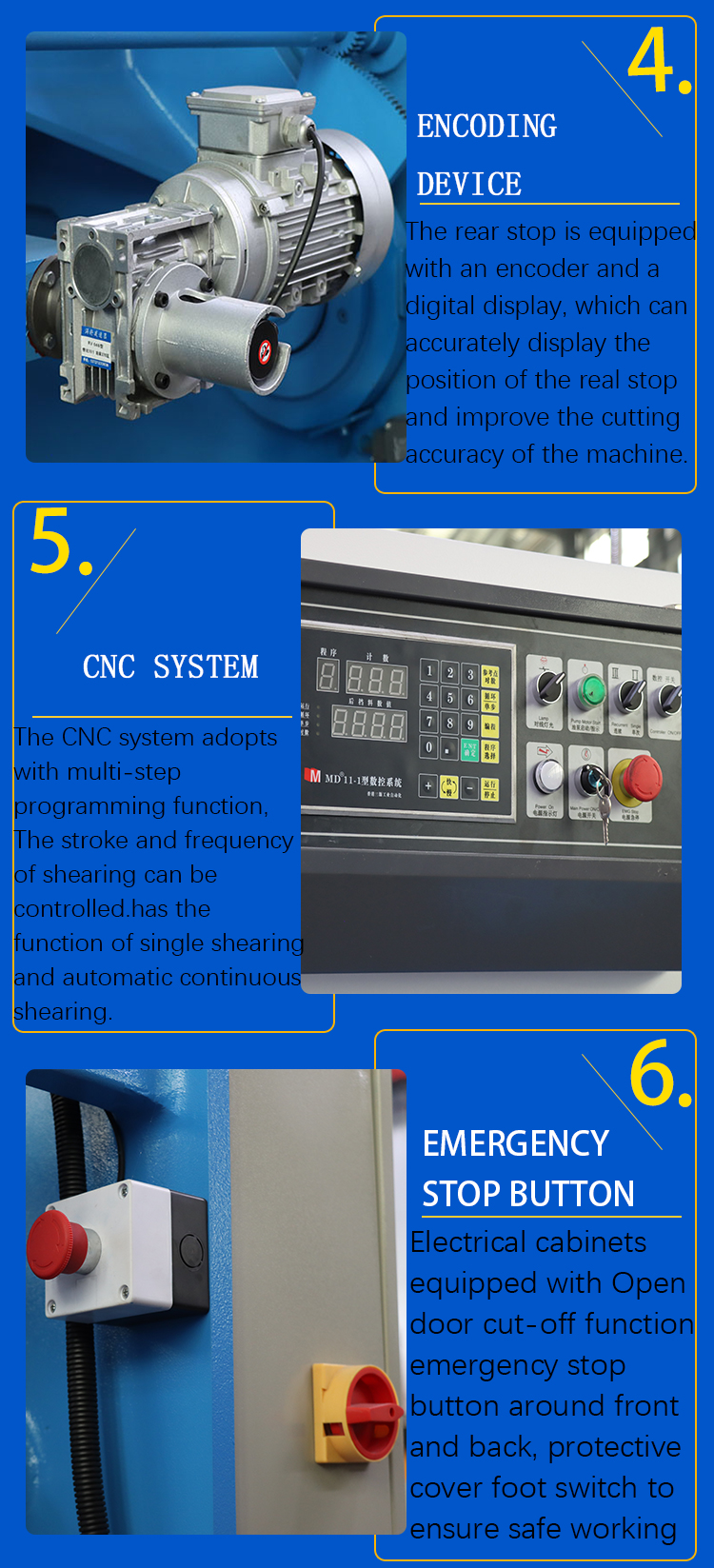

Detailed Images

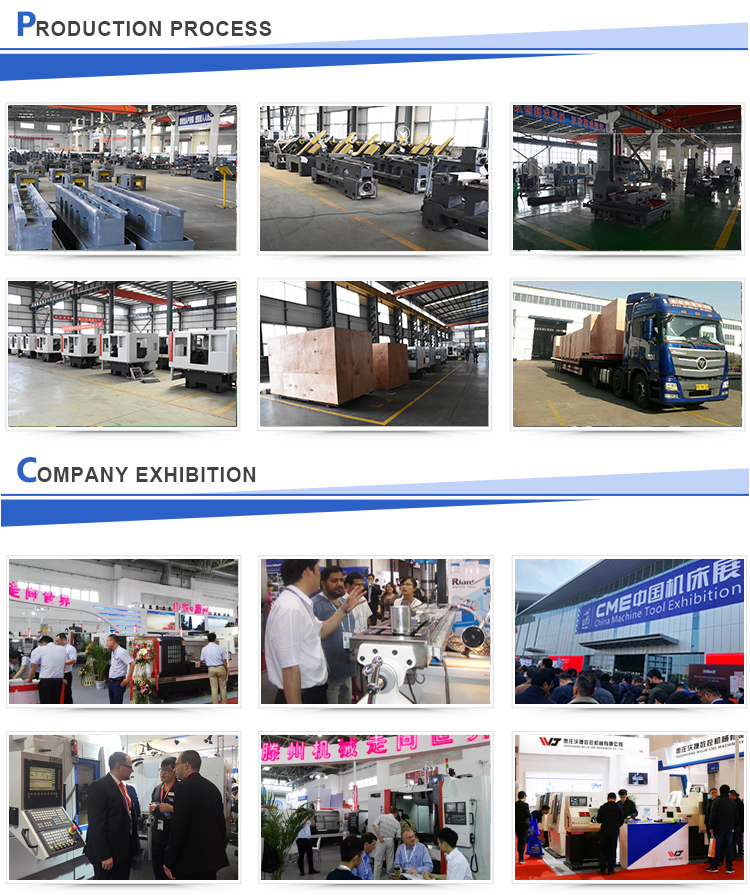

Company Introduction

Packing&Shipping

FAQ

1. What is the payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

When we receive the advance payment, we will start to make production.when the machine is ready , we will take pictures to you.after we got your balance payment. we will send the machine to you.

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine,gear hobbing machine and so on .

3.When is the delivery time?

A: If the machine you will order is standard machine, we can ready the machine within 15 days. if some special machines will be some longer. The ship time is about 30 days to Europe, America. If you are from Australia, or Asia, it will be shorter. You can place order according to delivery time and ship time.we will give you the answer accordingly.

4. What is your trade terms?

A : FOB, CFR,CIF or others terms are all acceptable.

5. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.but we will offer lifetime service for machine.

6. What is the package of the machines?

A: The machines standard will be packed in plywood case.

Contact Us